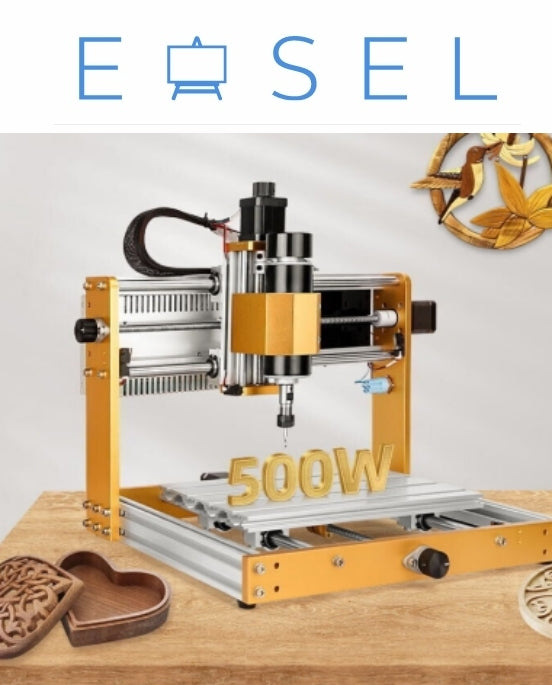

Connecting and Using Easel with LUNYEE 3018 CNC Router

Easel is a free, user-friendly online CNC design and control software developed by Inventables. The LUNYEE 3018 is a common desktop CNC router that typically uses a GRBL controller. This tutorial will guide you through the steps to connect Easel to your LUNYEE 3018 and perform basic operations.

Step 1: Preparations

-

Assemble and Check Your LUNYEE 3018:

- Ensure the router is correctly assembled according to its manual.

- Check that all wiring is secure, especially motor cables and limit switches (if your model has them).

- Ensure the spindle is correctly mounted and the bit is securely fastened (if installed).

- Connect the CNC router's USB cable to your computer.

- Turn on the power supply to the CNC router.

-

Sign Up for an Easel Account and Install Easel Driver:

- Open your web browser and go to the official Easel website: https://easel.inventables.com/

- If you don't have an account, click "Sign Up" to create one. If you already have an account, click "Log In."

- After logging in, Easel usually automatically detects if you have the Easel Driver installed. If not, it will prompt you to download and install it.

- Download Easel Driver: Click the provided link to download the Easel Driver installer for your operating system (Windows or macOS).

- Install Easel Driver: Run the downloaded installer and follow the on-screen instructions to complete the installation. This driver allows Easel to communicate with your CNC router through your browser.

-

(Optional but Recommended) Install CH340 Driver:

- If your computer fails to automatically recognize the LUNYEE 3018 (often shown as an unknown USB-SERIAL CH340 in Device Manager), you need to install the CH340 driver manually.

- You can find the driver by searching "CH340 driver download" online. Download and install it from a reliable source.

- After installation, reconnect the CNC's USB cable and check in Device Manager if it's correctly recognized (usually under "Ports (COM & LPT)" as "USB-SERIAL CH340 (COMX)," where X is a number). Note this COM port number, as you might need it later.

Step 2: Setting Up Your Machine in Easel

-

Log In to Easel and Start Setup:

- Log in to your Easel account.

- Easel will typically guide you through machine setup on your first login or if no machine is set up. You can also click your account icon in the top right corner and select "Set up new machine" or a similar option.

-

Select Machine Type:

- Easel will display a list of machines

-

Configure Machine Parameters:

-

Work Area:

- This is the maximum area your LUNYEE 3018 can carve. For a standard 3018 model, it's typically:

- Width: 300 mm

- Depth: 180 mm

- Height (Z-axis travel): 80 mm .

- Enter these dimensions in Easel. Ensure the units (mm or inches) match your input.

- This is the maximum area your LUNYEE 3018 can carve. For a standard 3018 model, it's typically:

-

Spindle Control:

- LUNYEE 3018s usually have a spindle that is turned on/off manually and its speed is controlled via a PWM (Pulse Width Modulation) signal from a separate controller or knob on the machine.

- In Easel, select "Manual Spindle Control" or a similar option if Easel doesn't directly control the spindle on/off and speed via software.

- If your 3018's control board supports spindle control via GRBL commands (M3/M5, Sxxxx) and you have wired it correctly, you can choose the corresponding automatic spindle control option. However, for beginners, starting with manual control is recommended to ensure the mechanical parts work correctly.

-

Homing Switches / Limit Switches:

- If your LUNYEE 3018 has limit switches installed and enabled in GRBL, you can enable "Homing Cycle" in Easel.

- If not installed or enabled, disable this option.

- Caution: Incorrect limit switch settings can cause the machine to crash. If unsure, disable it initially.

-

Work Area:

-

Connection Test:

- After configuring the parameters, Easel will attempt to connect to your CNC.

- Ensure your LUNYEE 3018 is connected to the computer via USB and powered on.

- Easel will automatically scan for available COM ports and try to connect.

- If successful, you'll usually see a green indicator or a "Machine Connected" message.

- If connection fails:

- Check if the Easel Driver is correctly installed and running.

- Check if the CH340 driver is correctly installed and the COM port is visible in Device Manager.

- Try manually selecting the correct COM port number (the one you noted earlier) in Easel's connection settings.

- Ensure no other software (like Candle, UGS, or other CNC control software) is occupying the COM port.

- Try restarting your computer and the CNC router.

Step 3: Performing an Initial Jogging Test

Once connected, Easel's "Carve" interface will usually become active. Before any actual carving, it's crucial to perform a manual movement test:

-

Open the "Carve" Panel: In the top right of Easel's design interface, there's usually a "CARVE" button. Click it to enter the carve preparation screen.

-

Safety Check:

- Ensure there are no obstructions in the carving area.

- Ensure the bit is raised to a safe height and won't hit the workpiece or clamps.

-

Use Jog Controls:

- In the "Carve" panel, you'll find movement control buttons for X, Y, and Z axes (usually arrow buttons).

- Set Step Size: Start with a small step size, e.g., 1mm or 0.1mm.

- Test X-axis: Click the X+ and X- buttons and observe if the machine's X-axis moves smoothly in the expected direction.

- Test Y-axis: Click the Y+ and Y- buttons and observe if the machine's Y-axis moves smoothly in the expected direction.

- Test Z-axis: Click the Z+ (up) and Z- (down) buttons and observe if the machine's Z-axis moves smoothly in the expected direction. Be extremely careful when jogging the Z-axis downwards to avoid crashing the bit into the wasteboard or limit blocks.

-

Check Movement Direction:

- If any axis moves in the opposite direction to the button's indication, you might need to modify the

$3(direction port invert) parameter in your GRBL settings. This typically requires a GRBL sender (like Candle, UGS, or Easel's built-in machine inspector/console in advanced settings). This is a more advanced operation; consult GRBL setting resources or seek help if you're unfamiliar.

- If any axis moves in the opposite direction to the button's indication, you might need to modify the

Step 4: Setting Up Your Material and Work Zero

Before starting any carving project, you need to tell Easel where your material is on the machine bed and the starting point of the bit relative to the material (often called "Work Zero" or "XYZ Zero").

-

Secure Material:

- Firmly secure the material you want to carve onto the LUNYEE 3018's workbed. Use clamps, double-sided tape, or other suitable methods to ensure the material doesn't move during carving.

-

Install Appropriate Bit:

- Select and install the carving bit suitable for your material and design. Ensure the bit is securely tightened in the spindle collet.

-

Position X and Y Axis Zero:

- Using Easel's jog controls, move the bit to the exact position on your material that you want to be the X and Y starting point. This is often the bottom-left corner or the center of the material, depending on your design.

- Fine Adjustments: Use smaller step sizes for precise positioning.

- Set X/Y Zero in Easel: Once the bit is in the desired position, find and click the "Set XY Zero" or similar button in Easel's "Carve" panel. This tells Easel that the current X and Y positions are the (0,0) point of your workpiece.

-

Position Z Axis Zero (Z Probing or Manual Set):

-

Manual Z Zero Set (Paper Method):

- Place a thin piece of paper on the surface of your material, directly under the bit.

- Using Easel's Z-axis down jog control, very slowly lower the bit.

- Gently try to pull the paper back and forth. When the tip of the bit touches the paper, causing a slight drag or just barely pinching it, stop lowering the Z-axis.

- Set Z Zero in Easel: Click the "Set Z Zero" or similar button. Easel will record the current Z-axis height as the material surface (i.e., Z=0). Then, remove the paper.

-

Using a Z Probe (If your 3018 is equipped and set up):

- Place the Z-probe block on the material surface and attach the alligator clip to the bit.

- In Easel, if there's a Z-probe option, follow its instructions. Typically, after clicking "Probe Z," the machine will automatically lower the Z-axis until the bit touches the probe block. Easel will automatically calculate and set the Z zero (accounting for the probe block's thickness).

-

Manual Z Zero Set (Paper Method):

-

Confirm Zero Points: After setting all three axis zeros, the preview in Easel should correctly display the bit's position relative to the material.

Step 5: Starting Your First Carving Project

-

Design or Import Your Project:

- You can use Easel's built-in design tools to create simple shapes and text.

- You can also import SVG files or G-code files. For the LUNYEE 3018, ensure the G-code is generated for a GRBL controller.

-

Set Material and Bit Parameters:

- In Easel's design interface, select the type of material you are using.

- Enter the diameter of the bit you have installed.

- Easel will suggest cutting parameters (Feed Rate, Depth per Pass, Spindle RPM) based on the material and bit. For the LUNYEE 3018, you may need to adjust these parameters based on your actual setup, especially the spindle RPM, as you might be setting it manually on the spindle controller.

- Important: For beginners, it's recommended to use conservative cutting parameters (slower feed rates, shallower depth per pass) to avoid damaging the bit or the machine.

-

Generate Toolpaths and Simulate:

- Easel will automatically generate the toolpaths based on your design and parameters.

- Use Easel's simulation feature to carefully review the toolpaths. Ensure they match your expectations and there are no potential collisions or issues.

-

Final Safety Checks:

- Re-confirm the material is securely clamped.

- Re-confirm the bit is securely tightened.

- Ensure you are wearing safety goggles.

- Raise the spindle to a safe height.

-

Start Carving:

- In Easel's "Carve" panel:

- Turn on the Spindle: If you have manual spindle control, turn on the spindle at its power switch or controller and adjust it to the appropriate speed.

- Click the "Carve" Button: Easel will display a final confirmation message. Read it carefully.

- Click "Start" or "Carve" again to confirm and begin.

- In Easel's "Carve" panel:

-

Monitor the Carving Process:

- During carving, closely monitor the machine's operation.

- Be ready to press the Emergency Stop button on your CNC control board or the "Pause" / "Cancel" button in Easel in case of any issues.

- Listen for any unusual noises, look for smoke, or excessive vibration.

-

Carving Complete:

- Easel will notify you when the carve is complete.

- Turn off the spindle.

- Wait for the spindle to stop rotating completely before moving the machine or removing the workpiece.

- Use the jog controls to move the bit away from the workpiece for easy removal.

Troubleshooting and Further Learning:

-

Connection Issues:

- Check the USB cable.

- Try a different USB port.

- Ensure Easel Driver and CH340 driver are up-to-date and correctly installed.

- Close other serial communication software that might be conflicting.

-

Poor Carving Results:

- Adjust cutting parameters (feed rate, depth per pass, spindle RPM).

- Check if the bit is sharp and correctly installed.

- Ensure the machine structure is rigid and there are no loose parts.

- Learn more about recommended cutting parameters for different materials.

-

GRBL Settings:

- The LUNYEE 3018 uses GRBL firmware. Understanding basic GRBL configuration parameters (viewed by typing

$$in Easel's console or a GRBL sender) can help you fine-tune machine performance. However, modify these parameters with caution, as incorrect settings can cause problems.

- The LUNYEE 3018 uses GRBL firmware. Understanding basic GRBL configuration parameters (viewed by typing